- Reale

- china

- 10-30days

- 300set /per one month

♥Quality control

Research and development control more than 10 technical engineers of the research and development team has many years of research and development experience, familiar with industrial product design principles, including circuit design, mechanical design, product design, energy conservation and environmental design.

♥Raw Material Control

Equipment parts Suppliers must undergo ISO quality system certification to ensure the quality and safety of materials, the company's quality inspection departments for each batch of materials must undergo standard inspection.

♥Finished product control

Huanrui has internal quality inspection departments and Third-party testing certification bodies. Internal Quality Inspection department to the finished equipment, the appearance of the instrument inspection, the instrument of the internal circuit and instrumentation testing software testing, instrument calibration, sample testing.

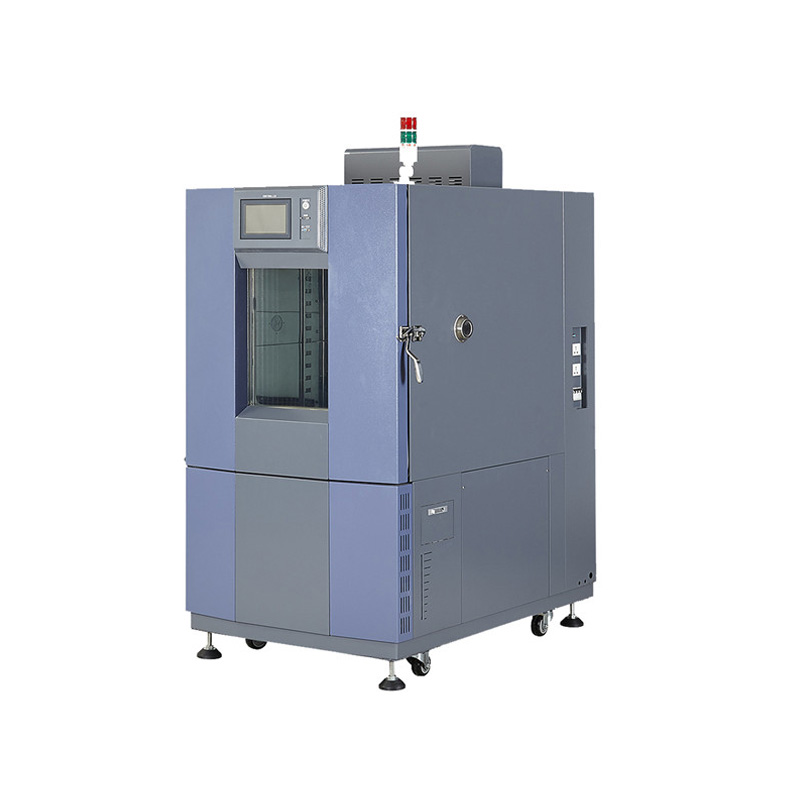

High Temperature Burn in Accelerated Aging Test Room

Uses:

Walk-in constant Temperature and humidity laboratory for industry large parts, semi-finish product,finish products

temperature and humidity environment testing. Such as computer terminal, car components.constant temperature

and humidity room is composed of control panel,switchboard,hydrating panel,fan, heater,humidifier,refrigerator

This equipment mainly used for create and keep temperature humidity constant space,completely automatic control

refrigeration,heating,dehumidify,humidification,supplementary humidified water,The equipment can be added (optional)

air exchange function,operator can long term work in it when exist poor volatile gas.Suitable for electrical, electronic,

instrument and other products, parts and components salt spray test chamber and material compatibility test of storage

transport using under high low temperature alternating,humid and hot environment.

Design Standard:

*IEC60068-2-1.1990 testing methods for low-temperature

*IEC60068-2-2.1974 testing methods for high-temperature

*GJB150.

Character:

*Temperature and humidity control by set parameter or program

*Whole process data record(option) record and trace whole testing process

*Each motor configure over current(over heat) protection, heater with short-circuit protection, ensure air quantity and heating reliable during equipment operation

*USB interface,Ethernet communication function, the communication and software extension of device can meet clients various requirements

*Adopt international popularity intelligent mode, Can adjust compressor cooling power automatically from 0% to 100%, Energy consumption reduced by 30% compare tradition heating balance temperature control mode.

*Key parts of refrigeration and electronic control all adopt international famous brand

*Requests, size, index, functions can customized.

Image:

Parameter:

High Temperature Burn in Accelerated Aging Test Room

Model | RHPW-4 | RHPW-6 | RHPW-8 | RHPW-13 | RHPW-17 | RHPW-21 |

| System | Balanced temperatuer & humidity control system | |||||

Testing temperature range | R.T-65℃~+120℃ | |||||

Humidity range | 20%-95%RH | |||||

Temperature fluctuation | ±0.5℃ | |||||

Humidity fluctuation | ±2.5%RH | |||||

| Temperture uniformity | ±2.0℃ | |||||

| Humidity uniformity | ±5.%RH | |||||

Temperture deviation | ±2℃ | |||||

Humidity deviation | ±3%RH (≥75%) ±5%RH(<75%) | |||||

Heat up time | 20℃~+80℃ within 60 minutes | |||||

Pull down time | 20℃~-55℃,-40℃,-30℃,-20℃,-10℃ within 120 or 90 or 60 minutes. | |||||

| Interior volume(m3) | 9.04 | 12.9 | 16.78 | 27.09 | 35.21 | 43.34 |

| Interior material | SUS#304 Stainless steel plate | |||||

| Exterior material | Model steel | |||||

| Insulation material | Rigid polyerethane foam +glass fibre | |||||

| Floor bearing load | 500Kg/m3 | |||||

| Refrigeration system | Air cooled (Water cooled type is option) | |||||

| Cascade type, hermetic/semitight compressor,CFC free refrigerant | ||||||

| Controller | Color LCD screen in English/Chinese, programing,communicating function | |||||

| Safety devices | No welding wire switch,compressor overheating and over current protection,over temperature protection, blower overload protection,dry heating machine protector,low water protection,fault warning system. | |||||

| Power | AC380±10% 50HZ 3 phase 4 ires+ground wires | |||||

Optional accessories:

*Test hole (Cable prot)

*Double open gate (Doors)

*Buffer room (Pass room)

*Mobile slope platform (Carry-in inclined)

*Temperature and humidity recorder (Reolving lamp)

*Ceiling blowing type (Entire ceiling blow-out duct)

*State indicator

*Pure water unit (Water purifier)

*Power outlet (Plug socket)

*Low humidity dehumidification equipment (Dehumidifier)