- REALE

- DONGGUAN,CHINA

- 20 days after payment

- 300 PCS/YEAR

Battery shock impact test machine is aim to test the safety performance of battery through different weights from different heights to impact different stressed area.

The battery shall have no flame or explosion after series of tests by this battery impact tester.

Standards:

IEC62133

UN38.3

SJ/T11169-1998

SJ/T11170-1998

UL1642:2008

UL2054:2008

QC/T 743-2006

QC/T 744-2006

GB/T18287-2000

GB 8897.4-2002

idt IEC60086-4:2000

Standard configuration:

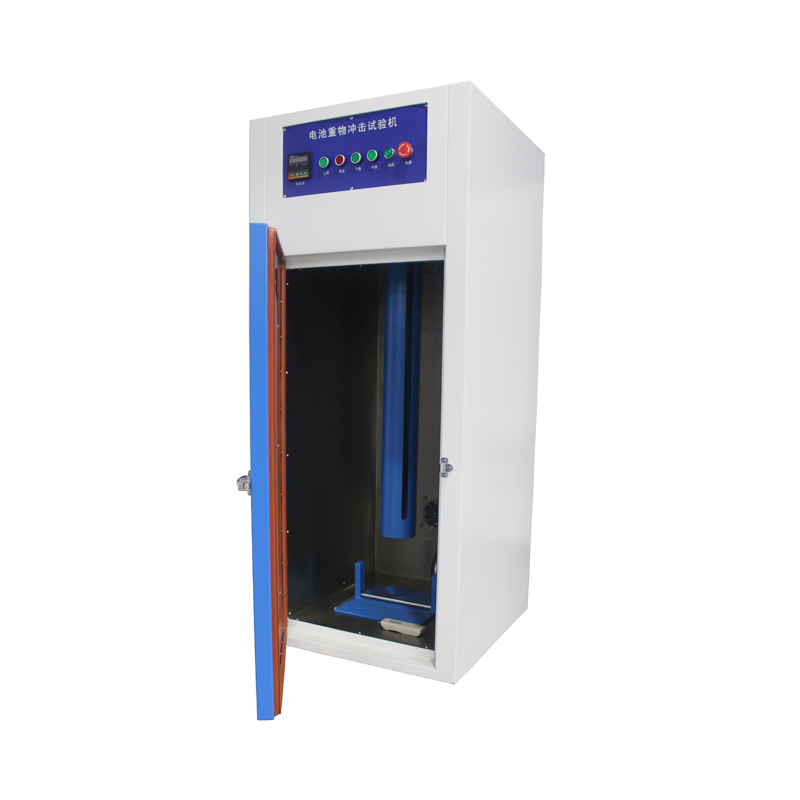

One main machine for testing machine, two standard falling balls, two safety bolts, one limiting pole.

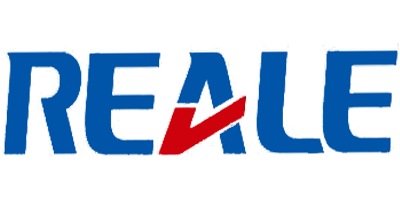

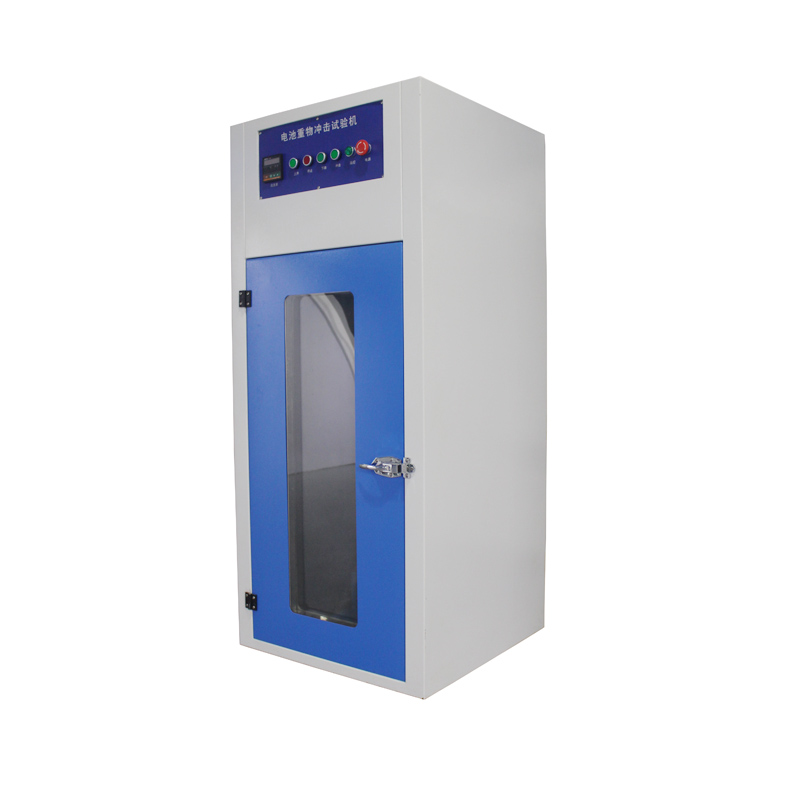

Battery Impact Tester

Structure:

Upper and lower impact surface: stainless steel plate

Inner box material: SUS#304 stainless steel plate

Carton material: cold plate paint

Filling material: glass wool

Impact method: free fall impact

Box Door: single door, double door, open observation window, cold handle door lock

Protection device: upper and lower limit protection switch, safety latch (located at the bottom of the guide tube, protects against sudden power failure)

SPECIFICATIONS | |||

Drop weight | 9.1kg±0.46Kg | ||

Drop height | 610 mm or 1000mm | ||

Impact way | Lift the ball to a certain height and release it. The ball falls freely in the vertical direction without tilting or shaking. | ||

Cross bar diameter | 15.8mm | ||

Internal material | stainless steel 304 | ||

External material | Galvanized cold plate paint treatment | ||

Exhaust port | On the back of the box 120mm | ||

Door | Single door, double layer, open observation window (tempered glass) with explosion-proof membrane, cold handle door lock | ||

Impact surface | stainless stelel plate | ||

Weight | about 145kg | ||

Power supply | AC 220V 50/60HZ | ||