- REALE

- China

- 15 days after deposit

- 30 sets a month

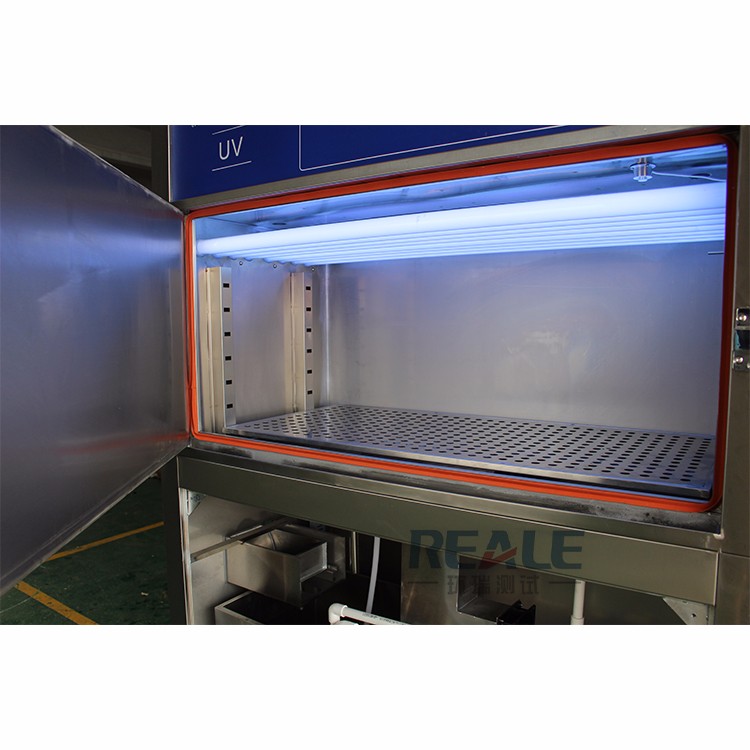

Uv resistant testing cabinet designed in simple and easy to operate. And Huanrui equips each device with English operation manual and operation video.

Uv Resistant Testing Cabinet

Product Description

UV resistant testing cabinet can simulate the environmental conditions of UV, rain, high temperature, high humidity, condensation, and darkness in the natural climate. By reproducing these conditions, they are combined into a loop and it is automatically executed to complete the cycle times.

Technicalparameters

Model | RUV-1 | RUV-2 |

System | Balanced temperature and humidity control system | |

Temp. range | RT~70℃ | |

Humidity range | 20~98%R.H | |

UV wavelength | 280~400nm | |

Distance from sample to lamp | 50±2mm | |

Centre distance between lamps | 70mm | |

Peak energy | 0.8~0.9W/m2 | |

Way of exposure | Steam condensation exposure, radiation exposure | |

Controller | Japan original temperature controller, imported programmable time controller | |

Internal dimension(cm) | 1140X390X400cm | 1100X600X400cm |

Meet the standards

1.IEC 61345: UV Test for Photovaltalic (PV) Modules

2.ASTM D4329-2005, Standard Practice for Fluorescent UV Exposure of Plastics;

3.ASTM D4587-2005, Standard Practice for Fluorescent UV-Condensation Exposures of Paint and Related Coatings

4. ASTM D5208-2001, Standard Practice for Fluorescent Ultraviolet (UV) Exposure of Photodegradable Plastics

5. ASTM D4799: Standard Practice for Accelerated Weathering Test Conditions and Procedures for Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)

6. ISO 4892-3: Plastics - Methods of Exposure to Laboratory Light Sources - Part 3: Fluorescent UV Lamps

7.ISO 48-3-2006, Plastics - Methods of exposure to laboratory light sources - Part 3: Fluorescent UV lamps

8.ISO 4892-1: Plastics - Methods of Exposure to Laboratory Light Sources - Part 1: General guidance