- REALE

- CHINA

- 15 days after deposit

- 30 sets one month

Huanrui company has a professional team of engineers who can design according to customer requirements,had obtained a patent certificate for an improved constant temperature and humidity test chamber. All constant temperature and humidity test chambers have obtained CE certification.

Temperature Humidity test cabinet

1.Summary of temperature humidity test cabinet

Programmable climate test room provides quality and accuracy, using world-renowned brand controllers, wide temperature and humidity range, and large cabinet size. The REALE environmental test chamber is ideal for quality and customizable simulated environmental tests. The climate chamber is widely used for the heat, cold, dry, and humidity resistance tests of various materials.

2.Meet the standards

Test A: Low temperature test method GB 2423.1-2008

Basic Environmental Test Rules for Electrical and Electronic Products

Test B: High temperature test method GB 2423.2-2008

Basic Environmental Test Rules for Electrical and Electronic Products

Test Ca: Constant humidity and heat test method GB/T 2423.3-2008

Basic Environmental Test Rules for Electrical and Electronic Products

Test Db: alternating humidity and heat test method GB/T423.4-2008

Basic Environmental Test Rules for Electrical and Electronic Products

3.Main parameter

Model | RHP-23 | RHP-80 | RHP-100 | RHP-150 | RHP-225 | RHP-408 |

System | Balanced temperature & humidity control system | |||||

Temp. range | -70°C~150C° | |||||

Humidity range | 20%~98%R.H | |||||

Temp. fluctuation | ±0.5℃ | |||||

Humidity fluctuation | ±2.5%R.H | |||||

Temperature deviation | ±2.0℃ | |||||

Humidity deviation | ±3%RH(≥75%)/±5%RH(<75%) | |||||

Heat up time | -20°C~150°C 45 minutes, -40°C~150°C 60 minutes, -70°C~150°C 75minutes | |||||

Pull down time | 20°C~-20°C 40minutes, 20°C~-40°C 60minutes, 20°C~-70°C 85minutes | |||||

Internal dimension (CM) | W30 | W40 | W50 | W50 | W60 | W68 |

H30 | H50 | H50 | H60 | H75 | H80 | |

D25 | D40 | D40 | D50 | D50 | D75 | |

Interior material | Stainless steel 304 | |||||

Exterior material | Backed paiting steel or stainless steel(SUS304) | |||||

Insulation material | Rigid polyruethane foam +glass fibre | |||||

Cooling system | 1. Air cooled (Water cooled type is option) 2. Singl section/cascade type, hermetic/semitight compressor,CFC free refrigerant | |||||

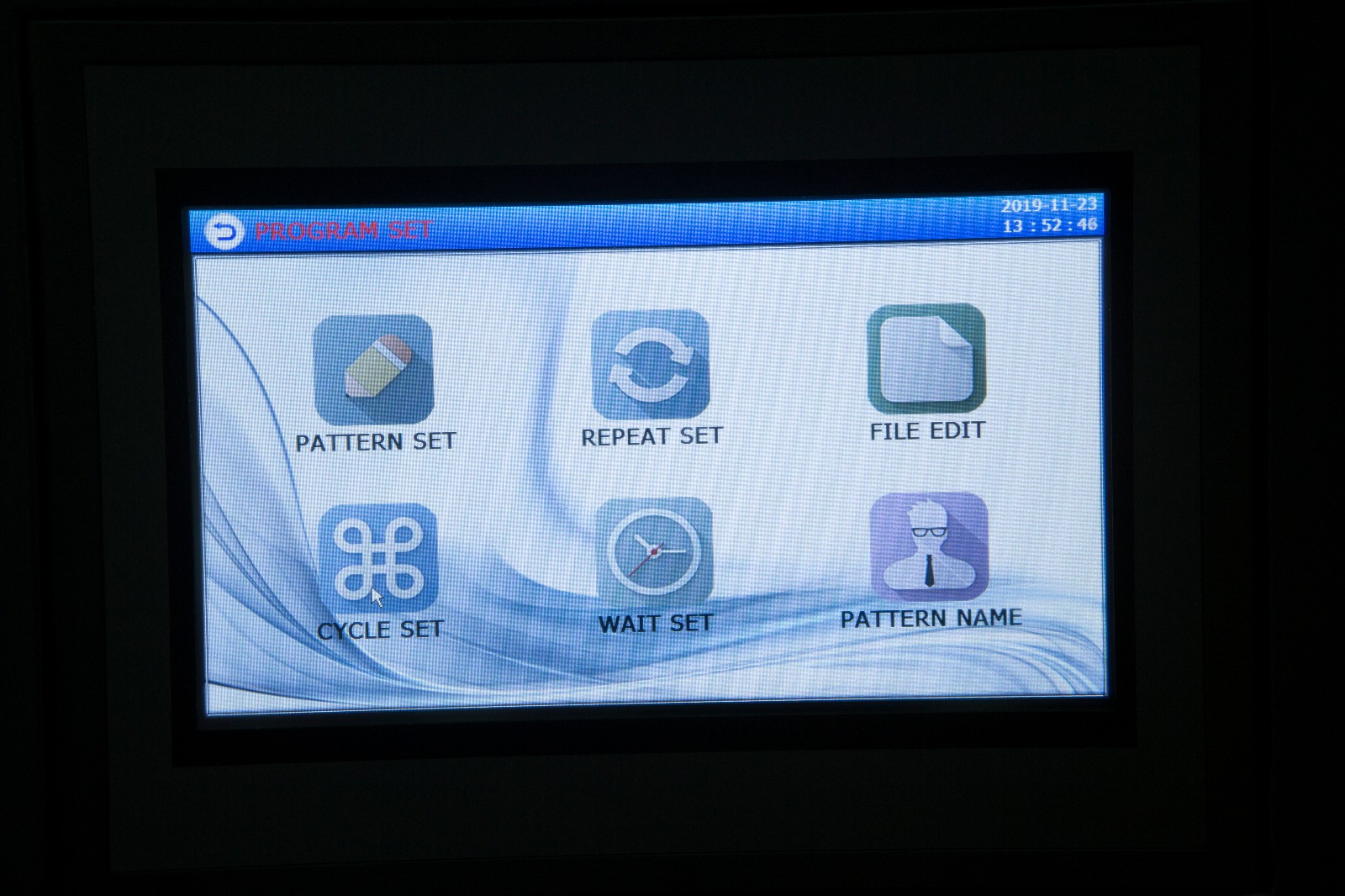

Controller | Color LCD screen in English/Chinese, programing,communicating function | |||||

Safety devices | No welding wire switch, compressor overheating and over current protection, over temperature protection, blower overload protection, dry heating machine protector,low water protection, fault warning system. | |||||

Standard accessories | one observation window, one test hole, two sets of test rack, one floodlight, one indicator light, four moving wheels, one humidifying tank, 2meters of power cord, communication interface | |||||

Power | AC380V±10% 50HZ 3 phase 4 wires+ground wires | |||||