- REAL

- CHINA

- 15 days after deposit

- 30 sets one month

Huanrui is a professional manufacturer of simulated environmental testing equipment.Thermal shock test chamber is the main product of Huanrui Company.Thermal shock test chamber is divided into two zone thermal shock test chamber and three zone thermal shock test chamber.

Double Duty Thermal Shock Chamber

Double Duty Thermal Shock Chamber consists of a high temperature zone and a low temperature zone. The test samples are sent to the high temperature zone and the low temperature zone through the basket to achieve the rapid temperature impact.

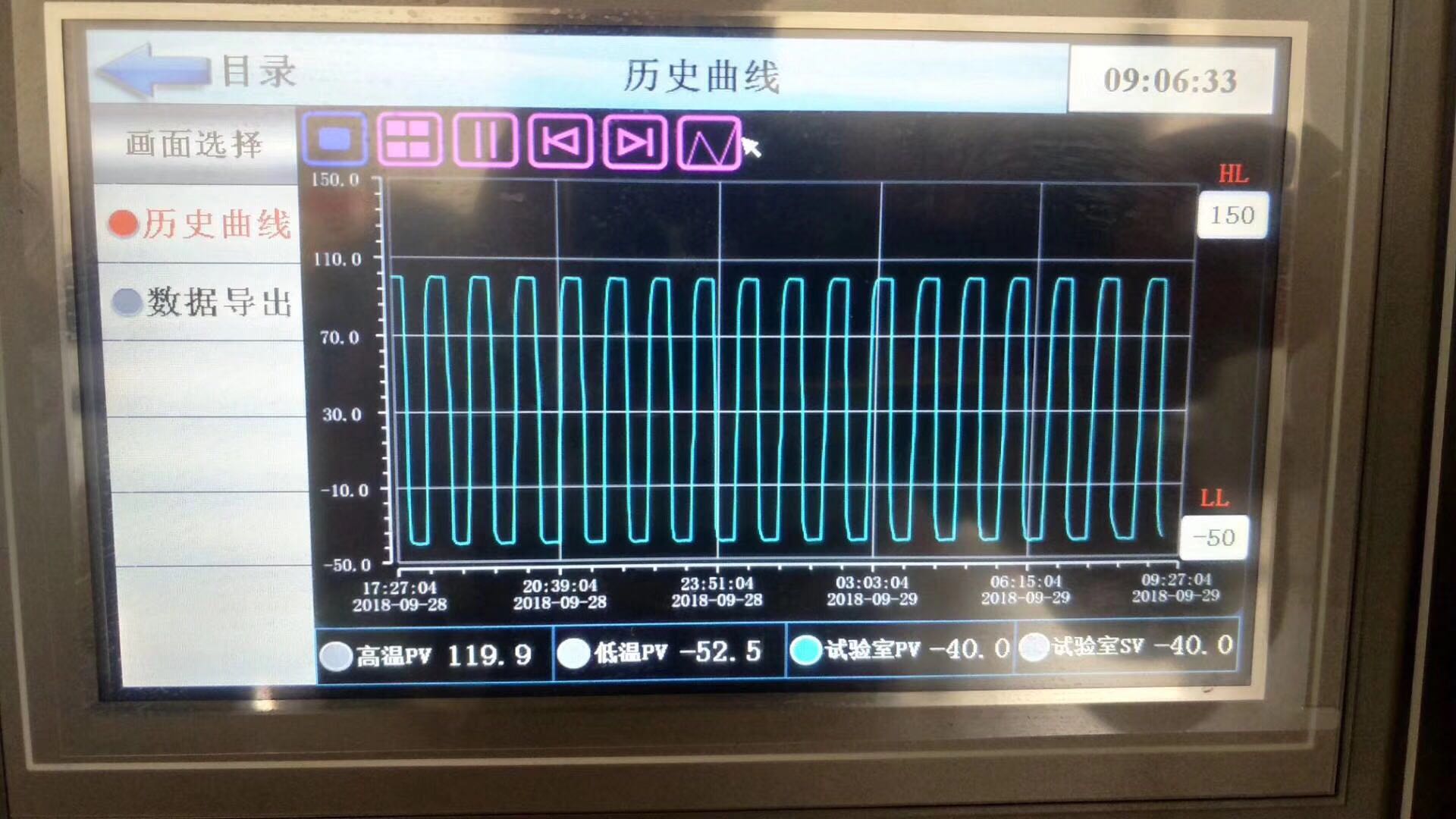

Temperature graph of double duty thermal shock chamber

Reference model and parameter

RTS-50 | RTS-80 | RTS-100 | RTS-150 | RTS-200 | RTS-300 | RTS-480 | ||

System | (BTC) Balanced temperature control system | |||||||

High temperature chamber | +60℃~200℃ Optional | |||||||

Preheating time | +60℃~200℃ About 20 minutes | |||||||

Low temperature chamber | -55℃~10℃, -70℃~10℃, -80℃~10℃ | |||||||

Precooling time | +20℃~-55℃ 60 minutes, +20℃~-75℃ 75 minutes, +20℃~-80℃ 90 minutes, | |||||||

Test chamber | -40℃~150℃, -55℃~150℃, -65℃~150℃ | |||||||

Recovery time | Within 5 minutes, heat exposure 30 minutes, low exposure 30 minutes, | |||||||

Transfer time | Within 10 seconds | |||||||

Temperature flucturation | ±1.0℃ | |||||||

Temperature deviation | ≤±2.0℃ | |||||||

Interior dimension(cm) | W | 40 | 50 | 55 | 68 | 68 | 80 | 80 |

H | 40 | 40 | 45 | 45 | 50 | 50 | 55 | |

D | 32 | 40 | 40 | 50 | 60 | 75 | 93 | |

Test weight (KG) | 3.5 | 5 | 5 | 5 | 10 | 12 | 15 | |

Interior material | SUS#304 Stainless steel plate | |||||||

Exterior material | Backed paiting steel or stainless steel(SUS304) | |||||||

Insulation material | Rigid polyruethane foam +glass fibre | |||||||

Floor bearing load | 500Kg/m3 | |||||||

Refrigeration system | Air cooled (Water cooled type is option) | |||||||

Cascade type, hermetic/semitight compressor,CFC free refrigerant | ||||||||

Controller | Color LCD screen in English/Chinese, programing,communicating function | |||||||

Safety devices | No welding wire switch,compressor overheating and over current protection,over temperature protection, blower overload protection,dry heating machine protector,low water protection,fault warning system. | |||||||

Power | AC380±10% 50HZ 3 phase 4 wires+ground wires | |||||||