- Reale

- china

- 10-30days

- 300set /per one month

♥Quality control

Research and development control more than 10 technical engineers of the research and development team has many years of research and development experience, familiar with industrial product design principles, including circuit design, mechanical design, product design, energy conservation and environmental design.

♥Raw Material Control

Equipment parts Suppliers must undergo ISO quality system certification to ensure the quality and safety of materials, the company's quality inspection departments for each batch of materials must undergo standard inspection.

♥Finished product control

Huanrui has internal quality inspection departments and Third-party testing certification bodies. Internal Quality Inspection department to the finished equipment, the appearance of the instrument inspection, the instrument of the internal circuit and instrumentation testing software testing, instrument calibration, sample testing

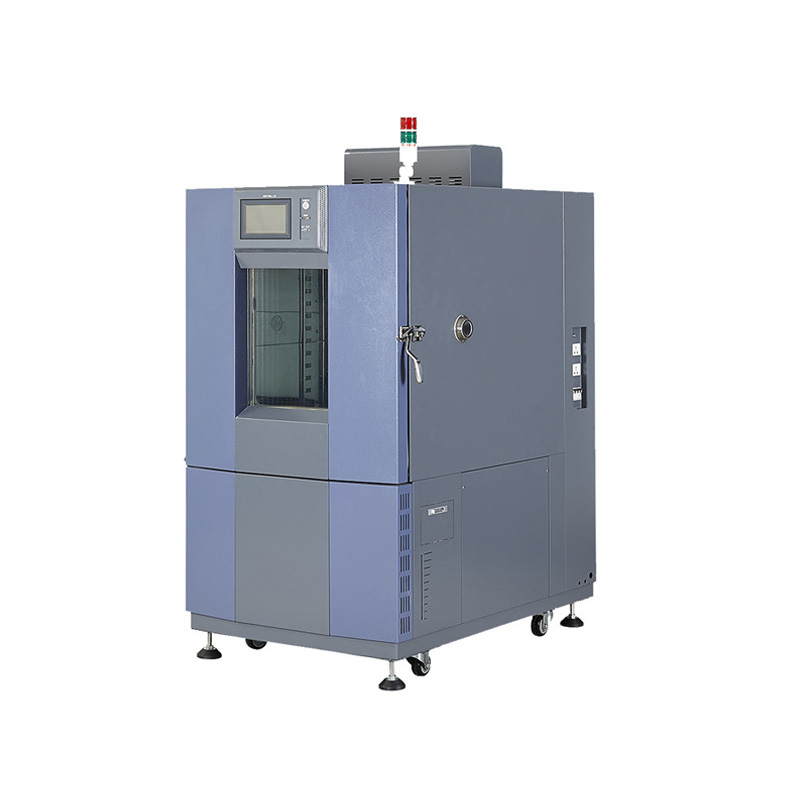

The temperature and humidity values set by the user can be maintained in the temperature and humidity test chamber, and these temperature and humidity values can also be alternately changed by program settings. If you need to test the performance of the product under high temperature, low temperature, high humidity, dryness, alternating temperature and humidity, then Huanrui temperature and humidity test chamber is your best choice.

| Model | RHP-23 | RHP-64 | RHP-80 | RHP-100 | RHP-120 | RHP-150 | RHP-225 | RHP-408 | RHP-800 | RHP-1000 | |

| System | Balanced temperature & humidity control system | ||||||||||

| Temp.Range | -20°C~150C°;-40°C~150C°;-70°C~150C° | ||||||||||

| Humidity Fluctuation | 20%~98%R.H | ||||||||||

| Temperature Deviation | ±0.5℃ | ||||||||||

| Humidity deviation | ±2.5%R.H | ||||||||||

| Heat Up Time | -20°C~150°C 45 minutes, -40°C~150°C 60 minutes, -70°C~150°C 75minutes | ||||||||||

| Pull Down Time | 20°C~-20°C 40minutes, 20°C~-40°C 60minutes, 20°C~-70°C 85minutes | ||||||||||

| Internal dimension | W | 30 | 40 | 40 | 50 | 50 | 50 | 60 | 68 | 100 | 100 |

| H | 30 | 40 | 50 | 50 | 50 | 60 | 75 | 80 | 100 | 100 | |

| D | 25 | 40 | 40 | 40 | 48 | 50 | 50 | 75 | 80 | 100 | |

| External dimension | W | 50 | 60 | 60 | 70 | 70 | 70 | 80 | 88 | 120 | 120 |

| H | 125 | 140 | 155 | 155 | 155 | 161 | 176 | 176 | 195 | 195 | |

| D | 90 | 110 | 110 | 115 | 123 | 125 | 125 | 150 | 155 | 175 | |

| Insulation material | Stainless steel 304 | ||||||||||

| Exterior meterial | Backed paiting steel or stainless steel(SUS304) | ||||||||||

| Insulation meterial | Rigid polyruethane foam +glass fibre | ||||||||||

| Refrigeration system | Single section/cascade type, hermetic/semitight compressor,CFC free refrigerant | ||||||||||

| Controller | Color LCD screen in English/Chinese, programing,communicating function | ||||||||||

| Safety Devices | No welding wire switch, compressor overheating and over current protection, over temperature protection, blower overload protection, dry heating machine protector,low water protection, fault warning system. | ||||||||||

| Standard Accessories | one observation window, one test hole, two sets of test rack, one floodlight, one indicator light, four moving wheels, one humidifying tank, 2meters of power cord, communication interface | ||||||||||

| Ambient Temp. | 5°C~35°C | ||||||||||

| Power | AC380V±10% 50HZ 3 phase 4 wires+ground wires | ||||||||||